Introduction to Ansys Mechanical

Two-day courseThis course provides an introduction to the Ansys Mechanical Environment of the Ansys software product suite.

The course focuses on use of the Mechanical user interface, which is included in Ansys Mechanical Pro, Ansys Mechanical Premium, and Ansys Mechanical Enterprise. Within this interface you read CAD geometry, assign material properties, apply loads and boundary conditions, define mesh controls, perform solutions, review analysis results, and generate an automatic html report.

The course devotes some time to theory and concepts at a very basic and practical level. These topics include finite element concepts, solutions of simultaneous equations, and contact models. These portions of the course emphasize practical theory concepts, which engineers need to understand in order to do finite element analysis.

Chapter 1 - Overview of Mechanical

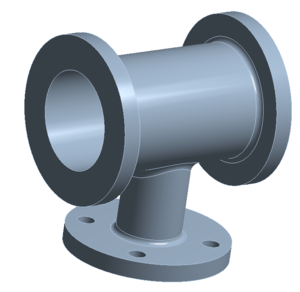

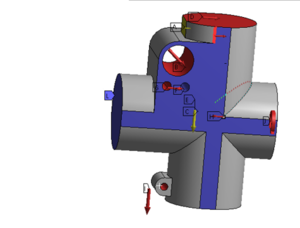

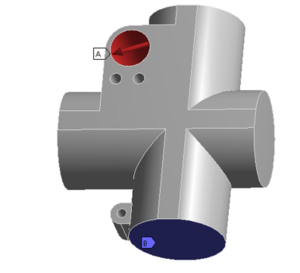

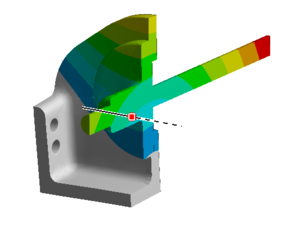

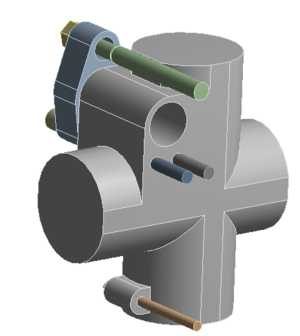

Workshop 1 – Static Stress Analysis of a Fluid Connector

Workshop 1 – Static Stress Analysis of a Fluid Connector

In this workshop we expose the user to the Ansys Workbench and Mechanical interfaces and perform a simple static stress analysis on the fluid connector. Basic file management is discussed as well.

Chapter 2 - General Overview of FEA

Workshop 2a – Element Types and Physical Behavior

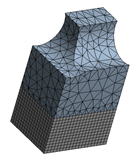

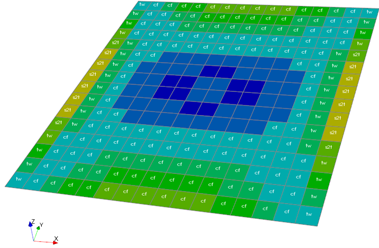

This workshop demonstrates how to control creation of lower order versus higher order elements and tetrahedron versus brick elements in Mechanical. It also provides students the opportunity to compare solution accuracy and computational resources for models with lower and higher elements using the Mechanical solution information object.

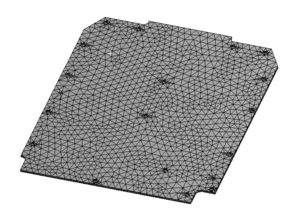

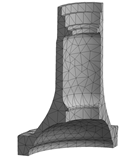

Workshops 2b – 2h. Mesh Controls on a Casting

This set of workshops demonstrate how to use some of the meshing techniques available in Mechanical to obtain accurate stresses with pinch controls, Multizone, Inflation, and Sphere of Influence methods .

Chapter 3 - Material Properties

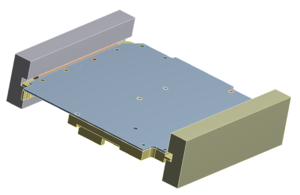

Workshop 3 – Assigning Material Properties to Parts in a PWB Assembly

This workshop uses various WB techniques to assign material properties. The WB Engineering Data Module is discussed in detail.

Chapter 4 - Loads and Boundary Conditions for Structural Analysis

Workshop 4 – Stress Analysis of a Pump Fluid End With Multiple Load Conditions

This workshop exposes all of the various structural loading options available within Mechanical.

Chapter 5 - Solution Options to Static Structural Analysis

Workshop 5 – Stress Analysis of a Pump Fluid End Using Direct and Iterative Solvers

We start the solution with an assembly and suppress all of the parts, except one for analysis. We use mapped meshing to set up the mesh. We use solution options to control which solver Mechanical uses for a static solution, direct or iterative. We use the solution information object to monitor the solution and to determine which solver is faster. For the iterative solve we use a preprocessing command object to set the solution accuracy. We turn the weak spring option off and on to determine the effect of weak springs on the solution.

Chapter 6 - Evaluation of Analysis Results

Workshop 6a – Stress Analysis of a Flanged Tube and Check of Results

The primary purpose of this workshop is to provide students the opportunity to check the results of the finite element model using hand calculations based on closed form solutions. We use symmetry boundary conditions to perform analysis on a quarter model of the flanged tube. We define a local cylindrical coordinate system and then use it to calculate axial, radial, and hoop component stresses. Finally, we compare the finite element model component stresses with stresses calculated using closed form equations for thin and thick walled pressure vessels. Students discuss with the instructor the correlation between the finite element and hand calculated stresses.

Workshop 6b – Postprocessing Options, Introduction to Scoping and Convergence

This workshop covers the extensive options available for results post-processing within Ansys Mechanical including cut planes, vector plots, legend manipulation, result display scaling, etc. We also get a first look at scoping of results and cover the concept of mesh convergence.

Chapter 7 - Evaluation of Local Stresses

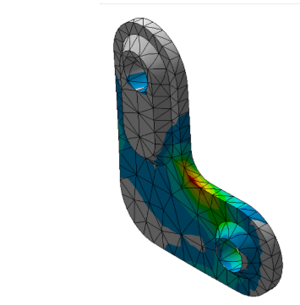

Workshop 7 – Stress Analysis of a Mechanical Link Using Scoping and Convergence

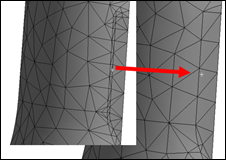

The focus of this workshop is use of scoping and convergence to evaluate local stresses. We start the workshop by doing stress analysis on a version of the link, which has a sharp corner, and students refine the mesh at the sharp corner to discover first hand the behavior of a stress singularity. Using model branching students add to the project a version of the link, which has a fillet where the sharp corner was present in the previous version. Students define a scoped stress object for stresses in the fillet and then use convergence to determine the stress to an accuracy of 2%.

Chapter 8 - Modal Analysis

Workshop 8 – Modal Analysis of an Alternator Bracket with and without Prestress

In this workshop we set up a model of an alternator bracket for normal modes analysis. We model the alternator attached to the bracket as a rigid point mass and monitor the change in natural frequencies and mode shapes as we change it to a deformable point mass. We also add standard earth gravity and note that Mechanical takes into account prestress effects if structural loads are present while performing a normal modes analysis.

Chapter 9 - Modeling Assemblies with Contacts

Workshop 9 – Stress Analysis of a Platform Assembly

This workshop is designed to provide students with practice modeling assemblies. We read the assembly into Mechanical and perform static stress analysis using default bonded contact to hold the parts together. We then use model branching to make a new version of the model, which has no separation contact instead of bonded contact for some of the connections, and we compare the behavior of the models with bonded and no separation contact in the connections.

Chapter 10 - Modeling Assemblies with Joints

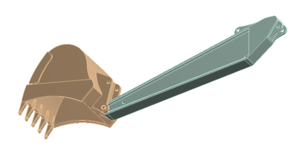

Workshop 10a – Modeling Joints in a Backhoe Lift Bucket Assembly

This workshop is focused on connecting parts together with a sample of the many joint types available in Mechanical. It explores the use of the Joint Configure to preview the possible motion of the jointed mechanism, as well as the Redundancy Analysis tool to verify the joints are constraining the motion as desired. Also, it uses the ability to specify parts as rigid instead of flexible to simplify the model.

Workshop 10b – Modeling Joints in a Backhoe Assembly with a Single Hydraulic Cylinder

This workshop builds on the skills developed in the previous workshop by setting up joints on a more complex model. With the higher complexity of the mechanism analyzed in this workshop comes a higher possibility of mistakes, so this workshop focuses on best practices that will aid in building up the set of joints incrementally while verifying the joints at each step of the process.

Chapter 11 - Rigid Body Motion in Static Solutions

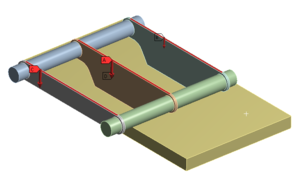

Workshop 11 – Stress Analysis of a Pipe and Plate Assembly with Rigid Body Motion

This workshop teaches the user to identify and fix locations in a model that may have rigid body motion due to contact regions that are not correctly defined. We also show the usefulness of a Modal analysis in determining rigid body motion in a static model; rigid body motion causes zero frequency modes in a normal modes analysis.

Chapter 12 - Interaction with CAD

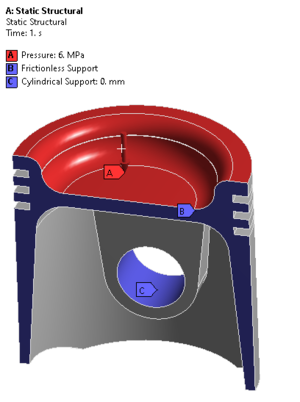

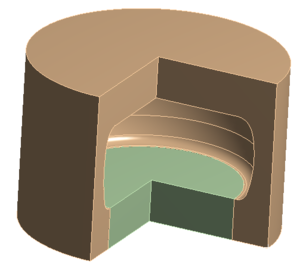

Workshop 12 – CAD Parameter Associativity of a Piston

The purpose of this workshop is to demonstrate associativity between CAD software, Workbench, SpaceClaim, and Mechanical. The starting point for this workshop is a parametric model in SpaceClaim format. SpaceClaim functions as the ‘CAD’ system for this workshop; the same principles apply to CAD packages. We transfer the model to Ansys Mechanical, set up and solve the model in a simple stress analysis. We then make changes to the geometry using SpaceClaim, update the model in Mechanical and re-solve. We demonstrate the usefulness of the Design of Experiments functionality within Workbench.

Workshop A: Thermal-Stress Analysis of a Heat Exchanger

Workshop A: Thermal-Stress Analysis of a Heat Exchanger

A first look at performing a thermal-stress analysis of a heat exchanger. The user is introduced to thermal loads, convection and temperature, and the model is solve. An energy balance is performed using the temperature reaction loads. Following this, the temperature profile of the heat exchanger is fed into a structural analysis through the Workbench project schematic and a simple structural analysis is performed.

Workshop B: Ansys Mechanical Integration with Ansys MAPDL (or Ansys Classic)

Workshop B: Ansys Mechanical Integration with Ansys MAPDL (or Ansys Classic)

This workshop exposes the user to the integration of Mechanical with MAPDL, or Ansys Classic. The students create named selections within Mechanical as well as command objects and then transfer the model into MAPDL. The student explores using MAPDL for object selections, defining loads and solving the model. This workshop is a first look at using MAPDL commands to augment an Ansys Mechanical analysis.

Workshop B: Ansys Mechanical Integration with Ansys MAPDL (or Ansys Classic)

Workshop B: Ansys Mechanical Integration with Ansys MAPDL (or Ansys Classic)

Workshop B: Ansys Mechanical Integration with Ansys MAPDL (or Ansys Classic)

This workshop exposes the user to the integration of Mechanical with MAPDL, or Ansys Classic. The students create named selections within Mechanical as well as command objects and then transfer the model into MAPDL. The student explores using MAPDL for object selections, defining loads and solving the model. This workshop is a first look at using MAPDL commands to augment an Ansys Mechanical analysis.