Ansys Mechanical Thermal Simulation

One-day courseThis course provides an introduction to thermal modeling capabilities in Ansys Mechanical. Ansys Mechanical handles conduction and radiation heat transfer including calculation of view factors for surface-to-surface radiation. Mechanical also handles convection heat transfer, primarily as a boundary condition based on a heat transfer coefficient and a bulk temperature. Material properties and heat transfer coefficients can be temperature-dependent.

This course is entirely workshop-based with no dedicated lecture component and takes place over a single day. The emphasis is placed on the creation and solution of practical thermal analyses rather than detailed presentation of heat transfer theory. The goal is to introduce the most important tools for heat transfer analysis and to show best practices for modeling common heat transfer problem types.

This is an advanced course, and attendees are expected to be comfortable with the basics of Ansys Workbench and Mechanical. It is recommended that attendees complete DRD’s Introduction to Ansys Mechanical course prior to attending this course. Engineers already proficient with Ansys Mechanical also have the course prerequisite.

Course Requirements:

Ansys Version used to create course content: 2023 R1

Ansys Version DRD instructor will use for the course: 2023 R1

Ansys Version(s) students may use for the course: 2023 R1

Registration for all classes will close 5 business days in advance of the class date.

Learn more: Agenda + Course Description

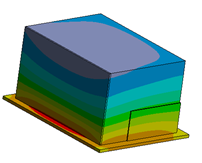

Workshop 1 – Hazardous Material Cabinet Subjected to Steady Temperature Load

In this workshop we model steady-state heat transfer in a hazardous material enclosure. This simplified analysis incorporates convection with the environment as well as internal conduction in a multi-part assembly. We introduce techniques for estimating and assigning convection coefficients based on the temperature difference between the fluid and the convection surface. Temperature-dependent material properties are created and assigned.

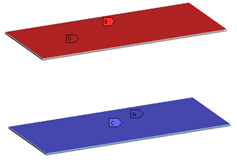

Workshop 2 – Parallel Plates with Radiation Heat Transfer

In this workshop we introduce radiation heat transfer. We compare the results from using radiation boundary conditions in FEA with hand calculations for a case of two parallel plates of known temperature.

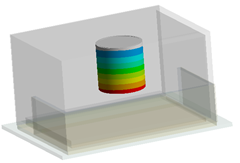

Workshop 3 – Hazardous Material Cabinet Thermal Analysis with Radiation

In this workshop we continue Workshop 1 by adding radiation to the model, which allows heat to be transferred to and from an internal cylinder containing hazardous materials.

Workshop 4 – Hazardous Material Cabinet Subjected to Fire

In this workshop we continue the analysis on the hazardous material cabinet, this time performing a transient thermal analysis in order to observe the temperatures of the materials after the exterior is exposed to fire.

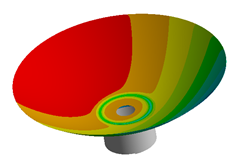

Workshop 5 – Antenna Subjected to Solar Loads and Thermal Stress

In this workshop we model solar radiation using an MAPDL Commands object. We also defeature components that are not important to a thermal analysis, then map the results from the defeatured thermal model onto a full-featured structural model in order to perform a thermal stress analysis.

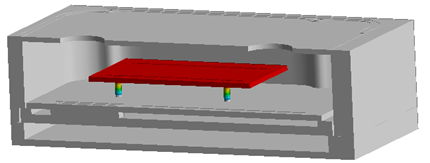

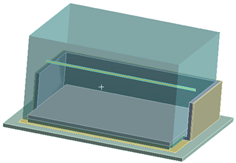

Workshop 6 – Heat Transfer Analysis of an Electronics Enclosure

In this workshop we demonstrate two uses of contact resistance: accounting for imperfect contact and modeling thin bodies with a specified resistance in the thickness direction.

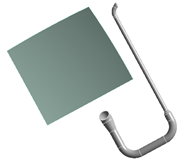

Workshop 7 – Effect of Exhaust Radiation Shield on Windshield

In this workshop we examine how a radiation shield surrounding a high-temperature exhaust pipe affects a nearby windshield.

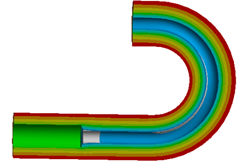

Workshop 8 – Thermal Analysis of Fuel Injection Nozzle with Fluid Flow

In this workshop we use Thermal Fluid elements to model fluid flow through a nozzle. The thermal analysis accounts for convection heat transfer between the fluid and the nozzle, as well as a specified mass flow rate of the fluid.

Workshop 9 – Heat Transfer in a Cabinet with Internal Convection

This workshop is designed to provide students with practice modeling assemblies. We read the assembly into Mechanical and perform static stress analysis using default bonded contact to hold the parts together. We then use model branching to make a new version of the model, which has no separation contact instead of bonded contact for some of the connections, and we compare the behavior of the models with bonded and no separation contact in the connections.

Workshop A – Radiation Heat Transfer from Exhaust Pipe to Gas Tank

In this appendix workshop, we give students the opportunity to practice setting up a heat transfer model without detailed instructions. The goal is to evaluate whether radiation from the exhaust pipe will bring the fuel tank to an unsafe temperature.