Ansys Composite PrepPost

one-day courseThis course is geared toward engineers who are designing and analyzing layered composites. The training will cover the correct and efficient use of this technology for the purpose of overcoming some of the inherent challenges in composite modeling such as capturing fiber orientation, model inspection, failure analysis, and parameterization. This training will teach attendees how to make high fidelity layered shell and layered solid models, save time at the post-processing stage, and more.

Prerequisites for this course are DRD’s Introduction to Ansys Mechanical course or equivalent practical experience using Ansys Mechanical. This is a challenging course for proficient users. Please do not register for this course if you do not have the prerequisites. Please contact DRD if you have questions or would like to discuss this with us at support@drd.com.

Course Requirements:

Ansys Version used to create course content: 2020 R1

Ansys Version DRD instructor will use for the course: 2022 R1

Ansys Version(s) students may use for the course: 2021 R1, 2021 R2, 2022 R1

Registration for all classes will close 5 business days in advance of the class date.

Learn more: Agenda + Course Description

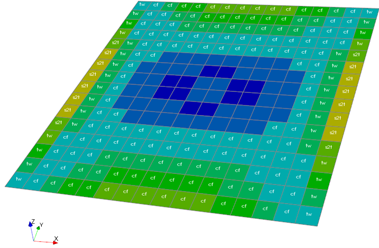

Workshop 1 - Basic Sandwich Panel

In this workshop the user will learn how to define new composite materials for analysis and start ACP from within Workbench. The user will then learn how to define fabrics, rosettes, oriented selection sets, and modeling plies to create a simple composite sandwich panel.

In this workshop the user will learn how to define new composite materials for analysis and start ACP from within Workbench. The user will then learn how to define fabrics, rosettes, oriented selection sets, and modeling plies to create a simple composite sandwich panel.

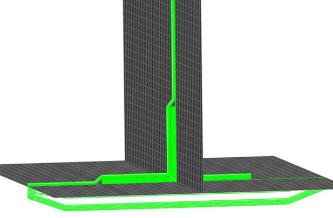

Workshop 2 - T-Joint

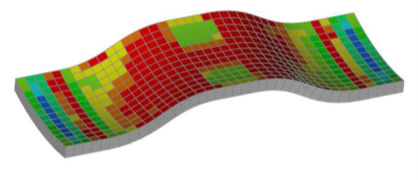

This workshop gives the user some experience with using multiple rosettes, multiple oriented selection sets, and tapering of core materials to define complex composite layups.

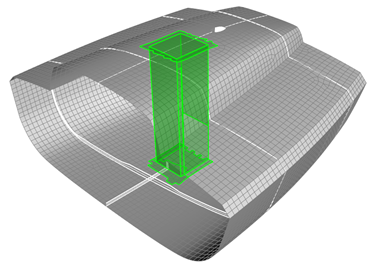

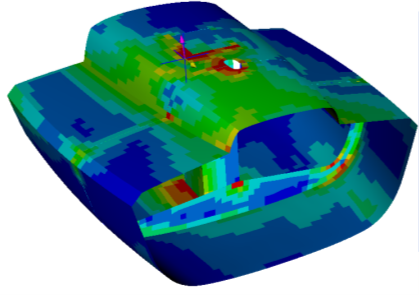

Workshop 3 - Class 40 - Selection Rules

In this workshop users will learn how to use selection rules to modify the composite layup of a class 40 boat in order to increase its reserve against failure.

Workshop 4 - Advanced Sandwich Panel

This workshop continues Workshop 1 – Basic Sandwich Panel. The layup is modified and reinforced in order to increase the panel’s strength, and the mesh is refined in order to obtain more accurate results. Selection rules and tapers are employed in order to create a desired layup.

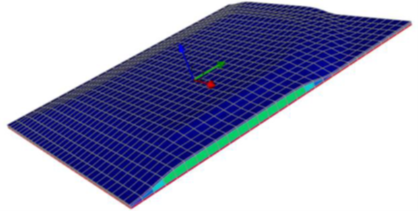

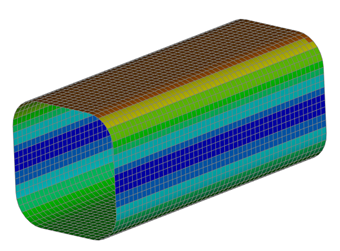

Workshop 5.1 - Solid Modeling

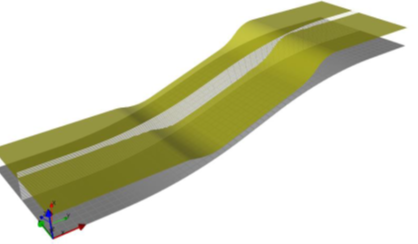

In this workshop, users will generate and evaluate a composite model of a doubly-curved tensile test specimen. This model will use solid elements instead of shell elements in order to accurately capture stress distributions in thick geometry where plane stress assumptions do not apply.

Workshop 5.2 - Solid Modeling with Cut-Off Rule

This workshop demonstrates the use of cut-off rules for ply tapering. It also goes through the procedure of applying a resin material to wedge elements that represent the tapered section where a ply starts or ends in a solid composite model.

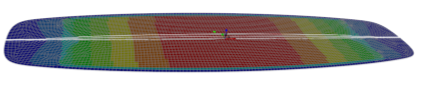

Workshop 6.1 – Kiteboard

This workshop will take users through the complete process of modeling, solving, and post-processing a composite model. Solid geometry will be used to generate a variable core thickness in a complex pattern.

Workshop 6.2 – Post-Processing

The boat model from Workshop 3 will be used to practice with a variety of post-processing tools, including sampling points to obtain through-thickness results.

Workshop 7 – Parameters in ACP

This workshop will use Workbench parameters to modify the laminate of a composite part. Multiple designs will be evaluated in order to identify which design has the best performance in terms of several composite failure modes.